Industrial training has always been high-stakes. Tiny mistakes can lead to serious injuries—and even fatalities. In fact, industrial companies have some of the highest fatality rates in the United States.

As a result, training programs often need to avoid risky scenarios or limit exposure to dangerous exercises to keep trainees safe. Plus, it’s also impractical (and very expensive) to have trainees repeat procedures in such a high-risk environment.

So, in most cases, workers end up learning as they go, and new workers are left unprepared for real-life situations—sometimes with costly consequences. For example, 70% of forklift accidents happen because operators aren’t properly trained.

But there’s a solution. Virtual reality (VR) offers a safe, immersive, and cost-effective way for workers to practice high-risk scenarios without real-world danger. In this ArborXR guide, we’ll show you how to implement VR industrial training successfully.

What Is VR Industrial Training?

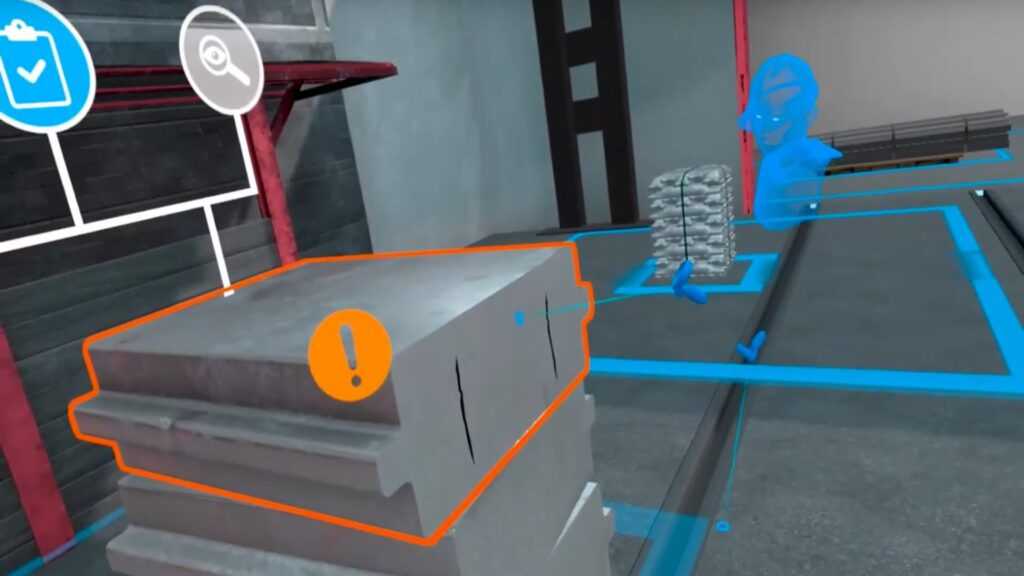

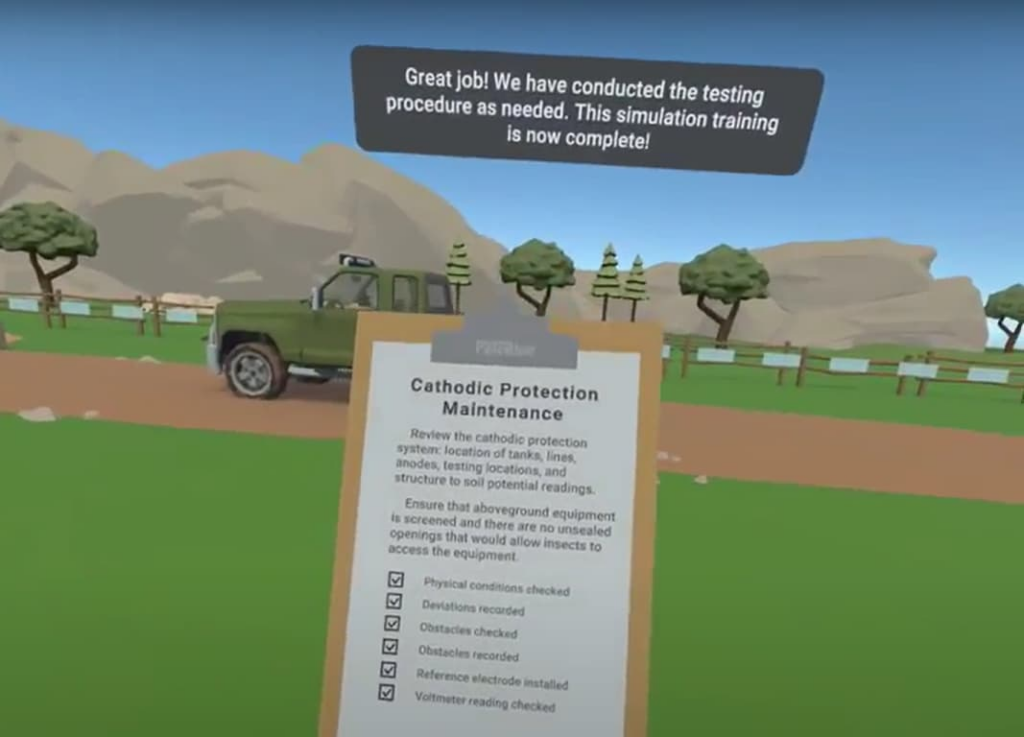

Virtual Reality (VR) industrial training is built to recreate real-world industrial settings and scenarios in a fully immersive virtual space. It can simulate everything from hazardous chemical spills to confined space operations, giving workers the chance to practice and sharpen their skills using VR headsets before applying them in real life.

A great example of this is the Western Electrical Contractors Association (WECA). In partnership with Motive.io, one of our developer partners, they’ve created a VR job site simulation that allows electrical apprentices to train and refine their skills safely. So far, over 1,200 apprentices have gone through this training, and the feedback shows they feel highly confident in handling any situation they might face.

Benefits of Using VR for Industrial Training

Effective Learning

VR industrial training provides a realistic, immersive, and hands-on experience for trainees. They can also repeat simulations as often as needed. These help improve retention and build confidence in their skills.

For example, PNX Lab developed a VR simulation for Cemex, where over 4,000 engineers could practice every part of cement production, from mixture preparation to packaging. The results have been impressive, showing better knowledge retention and quicker proficiency.

Improved Safety

The safety benefit of VR industrial training is twofold. First, it lets trainees practice high-risk scenarios without real-world dangers. Also, regular exposure to these virtual risks helps them handle actual risks with confidence and skill.

Good example? Numix’s Molten Metal Safety VR module for Constellium places learners in a virtual aluminum production environment to manage high-temperature processes and anomalies, reinforcing safety standards and preventing critical errors.

GWPro also offers Health and Safety VR training, allowing trainees to handle dangerous scenarios like equipment malfunctions and emergency evacuations safely.

Cost-Effectiveness and Scalability

VR training is also very cost-effective. It cuts down on the need for physical space, equipment, and travel expenses, which can significantly lower costs. Because it’s affordable and accessible, VR training is easy to scale, allowing companies to train large numbers of employees with ease.

For example, Paleblue created VR simulations for Saudi Aramco, covering inspection, electrical, and chemical modules. This method trains over 66,000 employees at a fraction of the cost of traditional training.

4 Best Practices for Effective VR Industrial Training

1. Set Clear Learning Objectives

Like any successful project, VR industrial training starts with clear learning objectives. These objectives are crucial because they define what the training is meant to achieve and shape all the decisions that follow. With clear goals, everything else falls into place:

- The specific scenarios and skills for the VR simulations

- The type of VR headsets and equipment needed

- How to define success and which metrics to track

So, what does a “clear” objective mean? It simply means setting SMART goals—specific, measurable, achievable, relevant, and time-bound. A good example might be increasing equipment operation proficiency by 25% within six months.

To define this, you need data. Start by identifying the exact skills and knowledge your trainees need. For instance, if safety is a priority, list the safety protocols and procedures that should be included. Get feedback from stakeholders and trainees to fine-tune these goals until they meet the SMART criteria.

2. Work With Expert Developer

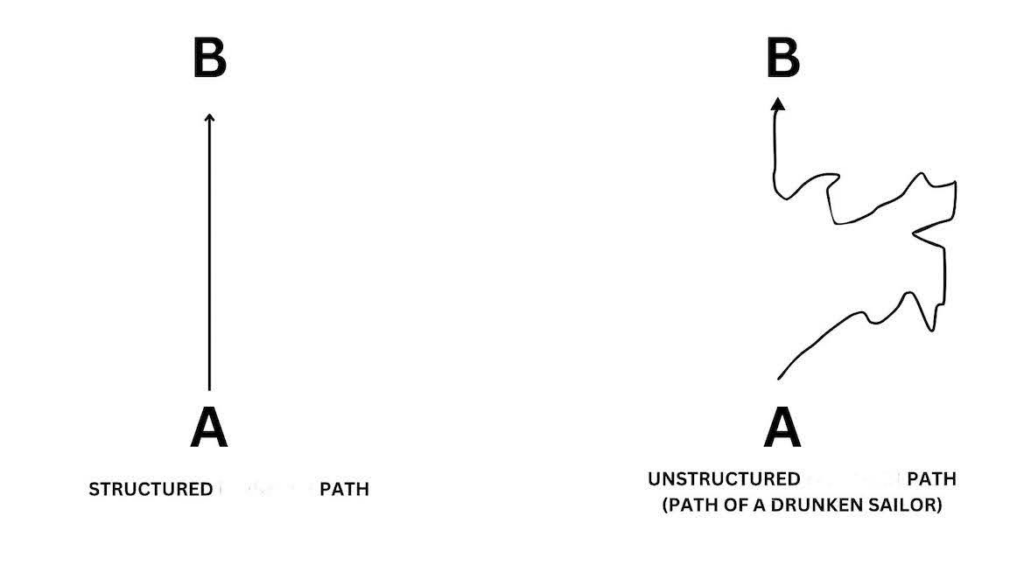

Implementing successful VR industrial training is easier when you have expert developers and content providers by your side. If you’re new to VR, the journey can feel a bit like wandering off course, taking more time and resources than needed to reach your goals.

With an experienced partner guiding you, the process becomes more structured, helping you achieve your training objectives faster and with fewer setbacks. Developers can help in two key ways:

- Developing quality content: The success of your training depends on the content. A good development partner will work with you to refine your goals and create high-quality content that aligns with them.

- Guiding implementation: Great developers can also provide hands-on support during implementation, ensuring your program stays on track—this is crucial for success.

Our XR Directory is a great resource for finding the right developer for your use case.

It features a carefully selected list of professional developers who specialize in creating custom and off-the-shelf VR training solutions for different industries.

3. Choose Durable Headsets & Peripherals

The right hardware can make or break the training experience, affecting everything from immersion to long-term cost-effectiveness. VR headsets and peripherals will be subjected to repeated use in demanding environments, so investing in durable, high-quality gear is a must.

So, what should you look for?

- Industry-Grade Durability: Choose headsets designed for industrial or commercial use. They’re built to handle more wear and tear than consumer-grade options. Good options are PICO 4E and Lenovo ThinkReality VRX.

- Comfort and Ergonomics: Make sure the headsets are comfortable for long periods, with adjustable straps and lightweight designs. Peripherals like controllers should be ergonomically designed to reduce strain during extended use.

- Compatibility with Training Needs: Pick peripherals that match the skills being trained. For instance, if you’re simulating equipment handling, ensure the controllers or gloves are accurate and responsive. Also, opt for a 6DoF headset instead of a 3DoF one for better movement range.

4. Opt For a Great XR MDM

When investing in headsets, you also need to think about how to manage them effectively. Without a dedicated XR MDM, you might face several issues, such as:

- Installing content and updates one headset at a time

- Losing track of device locations and statuses

- Lacking visibility into who’s using the devices and how

A specialized XR MDM, like ArborXR, addresses these problems. We’ve helped over 3,000 global companies, including more than 50 Fortune 500 companies, manage and deploy headsets for VR initiatives. Here’s what Kevin Marcum, Program Manager at Delta, has to say:

“If you are a company thinking of launching VR initiatives, you have to have an MDM. I can’t imagine having more than five to six headsets and not having data from them on ArborXR. It’s a game-changer for us.”

Kevin Marcum, Program Manager VR at Delta Air Lines

Let’s dive briefly into some of the key features that make this possible:

- Remote Device Management: Update device software, track locations, monitor battery levels, and adjust settings like WiFi and brightness—all from one place.

- Single and Multi-App Kiosk Modes: Restrict users to one or multiple apps using Kiosk Mode or ArborXR Home, respectively.

- Remote Experience Management: Reboot devices remotely, cast what users are seeing and directly guide them if necessary.

- Content Management: Receive content and updates directly from supported developers or remotely install apps and files from your ArborXR content library. Access a content library to manage and distribute content and updates to your headsets at scale.

VR Is the Answer for Smarter, Safer Industrial Training

VR has changed the face of industrial training and it’s just getting started. It allows you to conduct effective training without worrying about accidents or dealing with expensive programs.

To achieve the best results from VR training, set clear goals, work with expert developers, choose durable equipment, and use a reliable XR MDM like ArborXR. At ArborXR, we help you deploy and manage XR devices remotely, install and update content at scale, and get full control over in-VR experiences with kiosk experiences. Why wait? Sign up for free to see what ArborXR can bring to your VR industrial training table.